The largest aluminum project in the country

The South Aluminum Project of Iran is one of the most important projects in the country’s aluminum industry. This project with a production capacity of 300,000 metric tons of aluminum alloy in the first phase and a total capacity of about 1 million metric tons in 3 independent phases is known as the largest primary aluminum plant of the country, thus an economic advantage in the industry. In this smelter, the 430 kAh technology is being used for the first time, leading to reduction of energy consumption and operation costs, as well as optimum use of raw materials.

- Project location: Lamerd Energy Intensive Industrial Special Economic Zone, Northern Lamerd City, Fars Province

- Total project area: 200 hectares

- Project value: 1.2 billion dollars

- Project annual capacity: one million metric tons in three phases (about 350’000 metric tons each)

Main Parts of the Project:

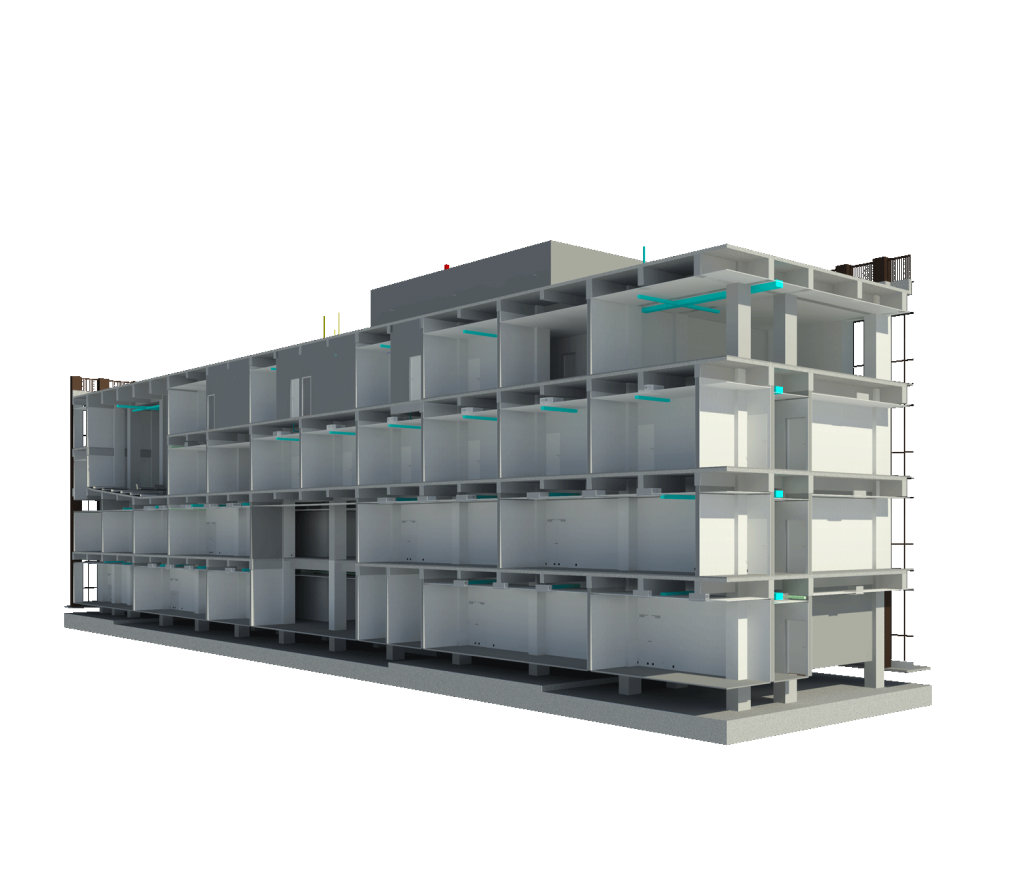

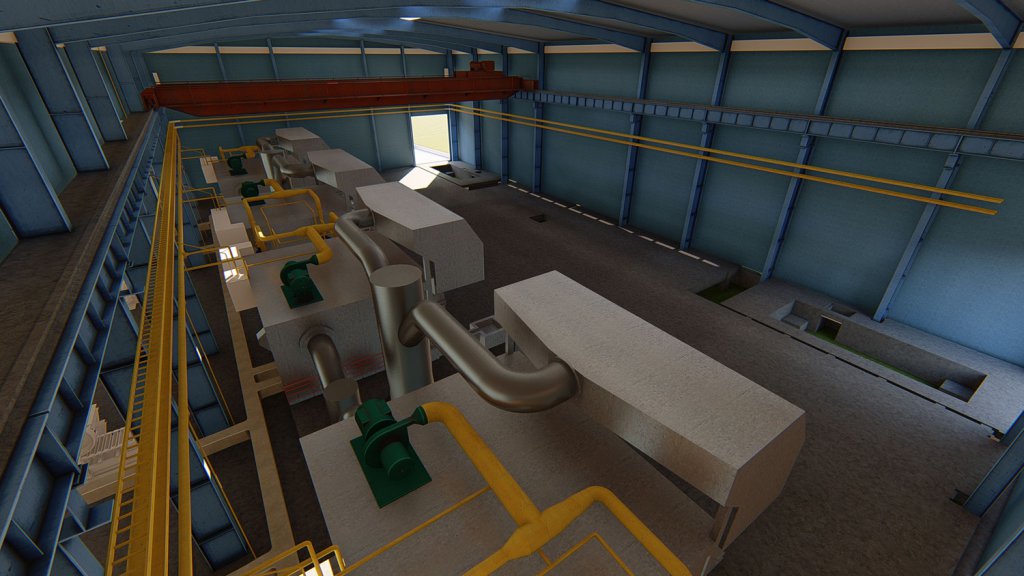

Potrooms: The first phase of this project consists of two potrooms in which electrolysis pots for aluminum production are located. The potrooms are about 1000 meters long and have totally 258 pots, 129 each. They are designed based on the 430 kAh technology and have a total production capacity of 300’000 metric tons of aluminum as a result.

Anode factory: It consists of three workshops: green anode shop, bakehouse, and rodding shop. In the green anode shop, 432 green anodes are made daily, which are then transported to the bakehouse. The bakehouse has 66 furnaces and an annual production capacity of 200,000 metric tons. In the rodding shop, 322 rodded anodes are produced daily, and sent to the potrooms afterwards. The remaining materials are sent back to the rodding shop, where they are separated from each other to be transferred to the related silos and reused in anode production.

Project Main Parts:

Smelter (Pot Room) – Casting House – GTC/FTC/Dedusting – Anode Plant